Explore Peel And Stick Backsplash Types And Heat Tests

In modern home decor, Peel and Stick backsplash products are popular for their easy installation and diverse design options. However, for peel-and-stick backsplashes used in high-temperature environments such as kitchens, consumers need more understanding and actual testing to ensure the product's heat resistance and performance. This article will introduce the different types of peel-and-stick backsplashes and explore the heat testing of these products to help consumers make informed purchasing and usage decisions.

Introduction to Peel and Stick Backsplash Products of Different Materials

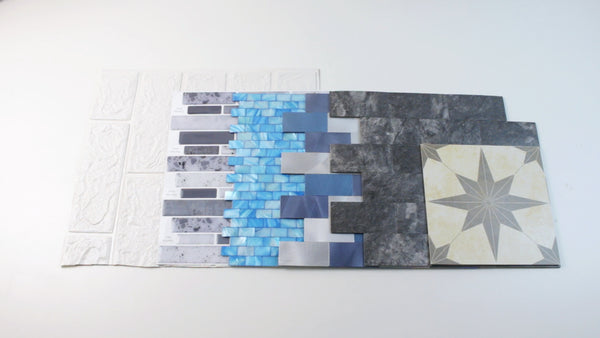

Compared with traditional ceramic tiles, peel and stick backsplash products can complete the backsplash modification at a lower cost and in less time, so they have become a popular choice among consumers. The peel and stick backsplash type currently on the market can be roughly divided into the following categories, they are:

a)Vinyl

b)Alu composite board

c)PVC

d)Shell

e)Foam

f)SPC

The Production Process of Each Product is Described in Detail Below.

Peel and Stick Vinyl Tiles

Vinyl products first print the pattern on the continuous material by printing and then print the isolation glue onto the seam through screen printing technology. The function of this isolating glue is to create the visual effect of mosaic stitches and to limit the subsequent dripping of rubber liquid within the formed frame. These transparent rubber drops form raised patterns that reflect the printed pattern under light, adding a three-dimensional feel.

It should be noted that due to the printing method, the pattern position of each product is fixed. A patch may look fine on its own, but when laid over a large area, the entire area will appear to be a repetition of the same pattern.

There are two types of adhesive backing for Vinyl products: one without foam and the other with foam. The foam-backed adhesive is relatively more suitable for different types of walls.

Peel and Stick ALU Composite Tiles

Alu composite board products mainly use aluminum-plastic panels as raw materials, which are cut and stamped to form small pieces of different specifications. They are then manually spliced and added with adhesive to complete production.

Since the surface is made of metallic aluminum, this type of product is more about displaying the unique texture of metal. Through different surface processes, different colors and patterns can be formed, ultimately forming a product with a serious sense of metal.

PVC Peel and Stick Backsplashes

Like the peel and stick backsplash products made of aluminum-plastic panels, the PVC peel and stick backsplash only uses PVC sheets as raw materials. PVC sheets include a base body, a PVC film (usually printed with various materials and patterns), and a wear-resistant layer on the surface of the PVC film. The production process is basically the same as ALU.

Self-Adhesice Shell Mosaic Tiles

Shell mosaic tiles use natural shells ground into small pieces of various specifications, and then undergo surface polishing and dyeing (some natural colors do not need to be dyed). Then arrange the small pieces neatly, use mesh stickers on the back to connect the small pieces into a whole piece, and finally add adhesive on the back.

Peel and Stick Foam Tiles

Foam wall stickers are made of polyurethane foam and surface decoration materials, and then the foam material is molded into the required thickness and shape through foam manufacturing. Next, the foam is cut and shaped to fit the wall, and the surface is printed with patterns or decorations. After printing, foam wall decals may be coated for added durability and decorative effect. Finally, apply adhesive to the back of the foam wall sticker to ensure it sticks firmly to the wall.

SPC Peel and Stick Tiles

The production process of SPC peel-and-stick tiles is similar to that of PVC peel-and-stick tiles, except that it is replaced by SPC sheets, which are cut, shaped and surface treated to achieve the required size, thickness and appearance requirements, which may include printed patterns or Decorate and apply a waterproof or abrasion-resistant coating. Finally, apply adhesive on the back of the SPC wall sticker to ensure that the wall sticker can be firmly attached to the wall and not easy to fall off.

Peel and Stick Backsplash Temperature Test

We have created a heating test video specifically to explore the impact of a peel and stick tile type product used in a kitchen backsplash installation on the heating of everyday kitchenware. The impact of heating on different products varies, and through this feature, we show how various products perform under heating conditions. If you are interested in this, please click to watch!

What Surfaces are Suitable for Peel and Stick Backsplash?

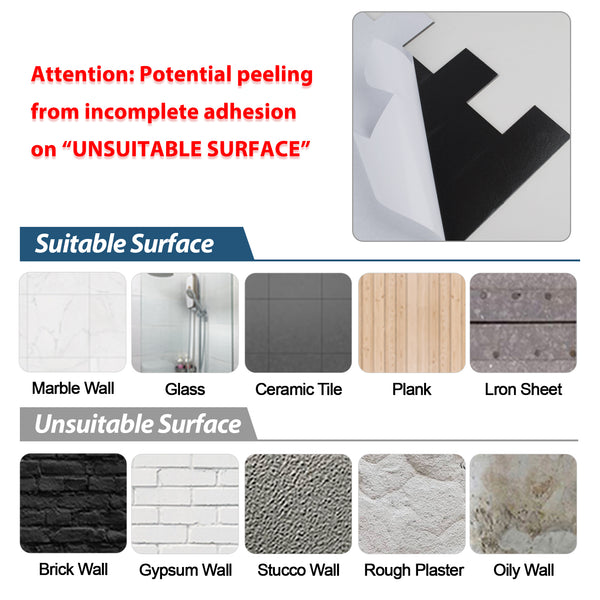

Before purchasing peel and stick tiles, consumers need to understand and ensure that the wall surface of the area to be installed is suitable. Peel and stick tiles mainly rely on the sticky adhesive on the back to attach the product to the wall. Due to the diversity of decoration materials, the wall may be tile, textured wall, existing backsplash, ceramic tile, laminate, wallpaper, drywall... etc. Which ones are suitable?

The first thing to confirm is that since it is a peel and stick product, its attachment to the wall mainly relies on the glue on the back of the product. Glue has two main properties: initial tack and viscosity. These two properties are opposite. A product with high initial viscosity will have weak durability, and a product with low initial viscosity will have strong durability. But there won't be much difference between the two in terms of normal use. The factors that affect the adhesion of the product on the wall mainly include the following four aspects:

a) The performance of the adhesive is not goodb) The amount of glue on the back glue is not enough

c) Wall problems prevent 100% bonding with adhesive

d)Temperature

Points a and b will not be described in detail. c and d need to be explained in detail. Walls made of different materials have different surface densities. For example, glass and smooth ceramic tiles have better surface density and smoothness than wallpaper, wooden, and textured walls. The smooth surface ensures full contact with the adhesive so that the adhesive can adhere. If the surface is not smooth enough, even if it has been fully cleaned, the subtle unevenness on the surface will hide dust that is invisible to the naked eye, affecting the fit and resulting in poor results.

The impact of different walls on the adhesive is similar to the impact on suction cups. As long as the surface is not smooth enough, the suction cup will fall off easily.

After understanding the principle, we can judge for ourselves whether the wall to be installed with self-adhesive wall stickers is suitable for the use of self-adhesive backsplash: as long as the surface of the material making up the wall is smooth enough, it is suitable for use. As for what the standards are, here are some suitable and inappropriate surfaces for everyone to use as a reference when making judgments.

Suitable surfaces: Ceramic Tile, Painted Drywall, Glass Surface, Laminate Countertop, Stainless Steel, etc.

Unsuitable surfaces: Textured Drywall, Unpainted Plywood, Brick Surface, Wallpaper, Rough Plaster, etc.

Frequently Asked Questions:

Peel and Stick Backsplash Not Need to Be Grouted?

Because the adhesive is added to the back, most peel and stick products are usually seamlessly assembled. In some cases, to highlight the border, a few products will retain small stitches, but there is adhesive underneath the stitches, so even if there are stitches, there is no need to grout after installation.

Where to Buy Peel and Stick Backsplash?

Peel and stick bachsplash products are easily available through different channels, including online and offline stores. However, since peel and stick backsplash products are not large (usually each piece is 12x12 inches in size) and not heavy, online stores will have more choices. You can easily find different types of peel and stick backsplash products on every online platform.

Leave a comment